I’m Patrick and today I’ll share something with you about what my colleagues and I do in the clean room at the Perugia laboratory, Italy, for the CMS Tracker.

In the CMS Perugia group we are all students, postdocs and researchers of INFN Sezione di Perugia, the University of Perugia and CNR-IOM. We all have different scientific backgrounds, such as experimental and applied physics, electronic engineering and mechanical engineering, and even different nationalities. We spend our work days either performing electrical measurements on detectors, or coding for data analysis and simulation applications. It is not all about work; during our leisure time and at weekends we enjoy long walks in the medieval and artistic historical center of Perugia, Umbria’s capital, or its scenic parks. Occasionally, we go to CERN for technical shifts or beam tests (our road trips!).

At our lab, we are currently involved in two major activities for the upcoming Phase-2 upgrade of the CMS Tracker, the innermost CMS sub-detector responsible for the reconstruction of the paths of high-energy charged particles. The CMS Tracker consists of concentric layers of many modules containing sensors that detect particles and we are currently involved as a center for process quality control characterization of the silicon sensor production, and as a module assembly center.

Most of our job is carried out in our clean room where everything has to be perfectly clean and dust free. We have to wear an overall garment (a bit similar to the uniform of a medical surgeon) constantly, which should completely cover our bodies in order to avoid dust particles and hair falling on the very sensitive silicon devices. Furthermore, we are working on thermal simulations for the Outer Tracker modules and on the modeling of the radiation damage in silicon sensors.

Standing (L-R): Alessandro Rossi (physicist, faculty member), Cristiano Turrioni (doctoral student in mechanical engineering), Francesco Bianchi (mechanical engineer, faculty member), Giorgio Baldinelli (mechanical engineer, faculty member), Patrick Asenov (physicist, post-doctoral fellow), Livio Fanò (physicist, faculty member). Kneeling (L-R): Valentina Mariani (physicist, post-doctoral fellow), Matteo Magherini (doctoral student in physics), Alex Di Chiaro (technician). Credits: Luca Tosti.

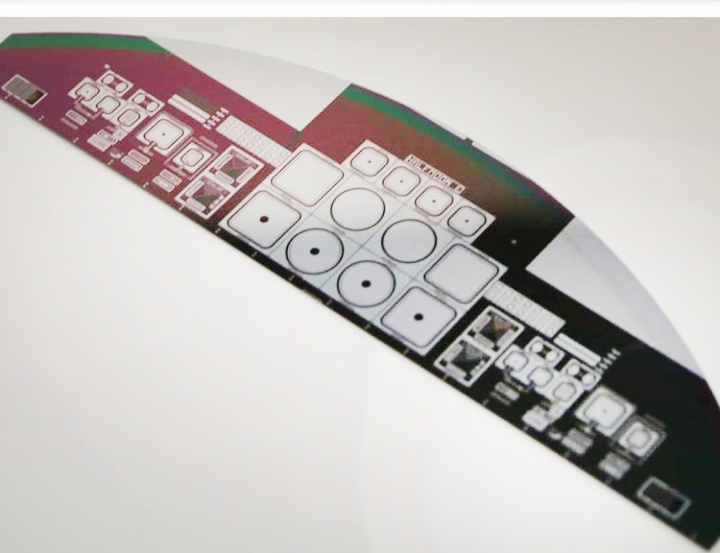

For the process quality control, we have been characterising lately halfmoons, the peripheral part of the wafers with the produced sensors of the Tracker that contain metal-oxide-semiconductor (MOS) capacitors, diodes and other test structures. Up to now, all the batches delivered to our institute have been characterized as good, which serves as a good indication of the excellent quality of the material and the process to realize the future Tracker sensors. In Perugia, we will characterise in total 25% of the halfmoons from the wafers produced for the Phase-2 Upgrade of the CMS outer Tracker.

The other exciting, as well as compelling, activity taking place in the Perugia clean room is the assembly of full Outer Tracker modules made up of pixel-strip (PS) sensors and other units (such as kapton, high-voltage tails, spacers, front-end hybrids carrying the readout chips, and service hybrids for power distribution, data serialisation and opto-electrical conversion). After the initial mechanical metrology for the sensor positioning, all module assembly steps are performed in our lab, such as the gluing, bonding and encapsulation along with standalone tests. The Perugia group will produce in total more than 17% of the PS modules for the Phase-2 Upgrade of the CMS Outer Tracker.

Spending time in such a unique environment gives us, young students and postdocs, the opportunity to acquire valuable hardware and software skills. Additionally, it teaches us to complete tasks with precision while dealing with tight deadlines.

I really admire our job because of the detailed knowledge of how tiny pieces, such as sensors and modules for the CMS Tracker, function independently on their own level and then combined together as part of the massive and powerful CMS detector.

Almost 100 m^2 ISO 7 clean room, divided into two ambients. The longitudinal configuration is optimised for sequential operations and assembly lines.

Credits: Cristiano Turrioni.

Disclaimer: The views expressed in CMS blogs are personal views of the author and do not necessarily represent official views of the CMS collaboration.